Page 4 - 3. Lesson Notes - Ch-3 Uses of Metals & Nonmetals (Alloys)

P. 4

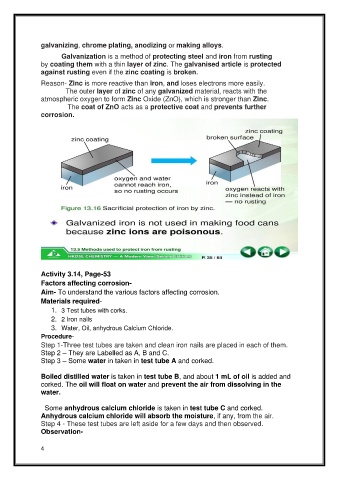

galvanizing, chrome plating, anodizing or making alloys.

Galvanization is a method of protecting steel and iron from rusting

by coating them with a thin layer of zinc. The galvanised article is protected

against rusting even if the zinc coating is broken.

Reason- Zinc is more reactive than iron, and loses electrons more easily.

The outer layer of zinc of any galvanized material, reacts with the

atmospheric oxygen to form Zinc Oxide (ZnO), which is stronger than Zinc.

The coat of ZnO acts as a protective coat and prevents further

corrosion.

Activity 3.14, Page-53

Factors affecting corrosion-

Aim- To understand the various factors affecting corrosion.

Materials required-

1. 3 Test tubes with corks.

2. 2 Iron nails

3. Water, Oil, anhydrous Calcium Chloride.

Procedure-

Step 1-Three test tubes are taken and clean iron nails are placed in each of them.

Step 2 – They are Labelled as A, B and C.

Step 3 – Some water in taken in test tube A and corked.

Boiled distilled water is taken in test tube B, and about 1 mL of oil is added and

corked. The oil will float on water and prevent the air from dissolving in the

water.

Some anhydrous calcium chloride is taken in test tube C and corked.

Anhydrous calcium chloride will absorb the moisture, if any, from the air.

Step 4 - These test tubes are left aside for a few days and then observed.

Observation-

4